Some Ideas on Industrial Water Treatment You Should Know

Table of ContentsSee This Report on Industrial Water TreatmentThe Main Principles Of Industrial Water Treatment Not known Incorrect Statements About Industrial Water Treatment Indicators on Industrial Water Treatment You Should KnowIndustrial Water Treatment - An OverviewIndustrial Water Treatment Fundamentals Explained

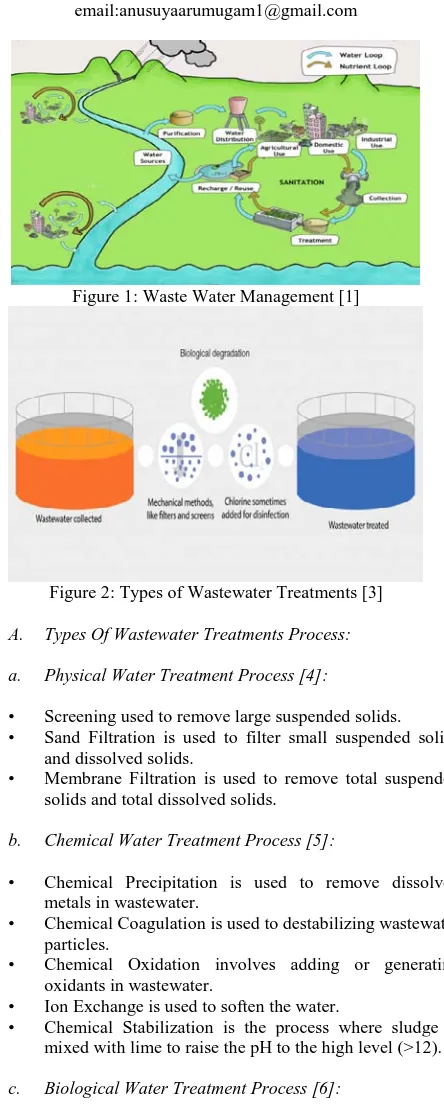

A typical saying in the past was "the option to contamination is dilution." This is not the most efficient treatment approach due to the fact that even percentages of toxins, such as some pesticides, can develop up, or bioaccumulate, in body fat in time. It is likewise not the preferred approach due to the fact that it sends out the message that polluting the environment is an acceptable course of action.

Sometimes, the particles that require to be filtered out throughout water treatment are extremely small. This makes them less likely to settle out and less most likely to be removed. industrial water treatment. Chemicals called coagulants and/or filter help are added to the water and mixed in (flocculated) to make the great particles stick to form larger particles that can much better settle out or be filtered out better.

The purpose of these 2 actions is to enhance the efficiency of the staying treatment processes. Settling. For centers treating water which contains a great deal of solids, settling or sedimentation is a typical treatment step. The procedure slows the flow of the water in a pond or basin so much heavier products can settle to the bottom.

The Ultimate Guide To Industrial Water Treatment

For plants treating extremely contaminated raw water, settling might be utilized as the very first step in the treatment plant (presedimentation) and again following the coagulation and flocculation steps. Purification. There are numerous methods of filtration used in water treatment. The selection of which type to use is normally a function of the raw water quality.

The product utilized is usually a granular medium such as sand, crushed anthracite coal, or activated carbon. Some facilities layer different types and sizes of media. Together with varying the size and type of filter media, centers are likewise created to run at various flow rates through the filter media.

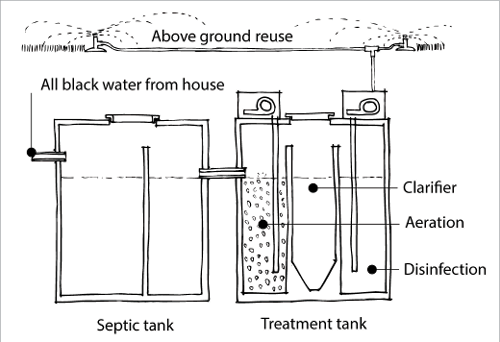

Another type of filtration that was more commonly used in the late 1990s and early 2000s is membrane filtering. It takes place by requiring water through a membrane barrier. A membrane resembles a state-of-the-art coffee filter. As water under pressure streams through the membrane, impurities and organisms are recorded on the membrane and not permitted to travel through.

The 9-Minute Rule for Industrial Water Treatment

Membrane filtration is getting use in the United States for special applications and in mix with other types of filtration. Disinfection. Purification and the steps prior to filtration concentrate on the physical removal of impurities in the water. In addition to physical elimination, it is still important to supply chemical disinfection.

Chlorine was first utilized in the United States in a water-treatment plant in 1908. The benefit of see it here chlorination is that it continues to kill germs as water moves through pipelines to the tap. Its disadvantage is the possibility of disinfection spin-offs. Excess chlorine in water can combine with natural material in the water to form compounds such as trihalomethanes, which can cause liver, kidney, or main anxious system problems, and are connected to an increased risk of cancer over a life time exposure.

Infections and giardia are efficiently eliminated by chlorine. Over time, researchers have actually found that some organisms such as Cryptosporidium are resistant to chlorine. Cryptosporidium increased to public attention in 1993 when it sickened over 400,000 individuals, killing a hundred, in Milwaukee, Wisconsin. Mainly because of this scare, brand-new or amended U.S.

The 6-Second Trick For Industrial Water Treatment

Other Chemical Treatments. Chemicals are included to drinking water to adjust its firmness or softness, pH, and alkalinity. Water that is acidic is really corrosive to the pipelines and materials with which it enters into contact. The addition of sodium hydroxide can minimize corrosivity and extend the service life of pipelines, tank, and structure plumbing systems.

Getting My Industrial Water Treatment To Work

The earth naturally provides filtering of tiny pathogens. It does not constantly supply appropriate protection against viruses or chemicals that are disposed on the ground. Groundwater normally contains higher concentrations of metals like iron and manganese since these metals happen naturally in the earth. Groundwater might also be much more difficult than surface water.

Some groundwater materials are not dealt with at all, while others may be filtered and decontaminated. Similar to surface area waters, the quality of the source determines what treatment actions are needed. Water supply in the United States send reports every month to state or federal regulative firms, summing up treatment-plant efficiency and tasting outcomes.

The Buzz on Industrial Water Treatment

Orders to boil the water are usually jointly issued by the state health firm and the drinking-water system quickly after a problem has actually been discovered (most likely by means of telephone and radio) (industrial water treatment). Public notifications about problems with regular tracking results or the failure to gather required samples would generally be dispersed in the newspaper or via the water energy's annual water quality report (also called a customer self-confidence report).